The Process Of Recycling Diamonds

The global diamond industry is transforming, embracing sustainability like never before. While the end consumer is most concerned about the "Four Cs"—carat, color, clarity, and cut—jewelry companies are now incorporating a fifth "C" into the equation: Circular Economy. By strategically purchasing recycled diamonds, companies can adhere to sustainable practices while providing high-quality, great-value stones that are imperceptible to newly mined diamonds to customers. In this article, we delve into the intricate process of diamond recycling.

The Recycling Process: A Detailed Breakdown

The first step involves purchasing mixed diamonds, often sourced from melt or scrap jewelry. It's crucial to point out that diamond, being the hardest substance known to man, remains unaffected by this process. This primary collection serves as the raw material for recycled diamonds.

Acid Boiling & Synthetic Detection

The mixed diamonds undergo boiling in a specialized acid solution to remove foreign substances. Cubic Zirconia (CZ), a commonly used diamond substitute, is frosted during this stage to differentiate it from genuine diamonds. After this, synthetic diamonds are detected and isolated using advanced technology like Synth Detect machines.

Sorting by Shape and Quality Metrics

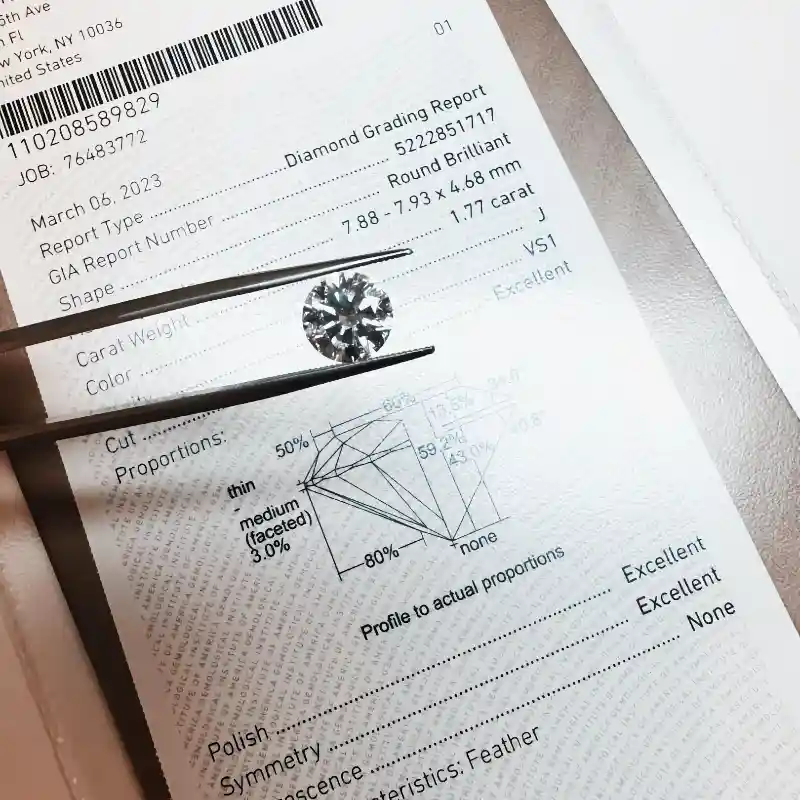

The next phase involves sorting diamonds by their shape. Shapes like round, oval, emerald, and others are separated into different categories. These sorted diamonds are further classified based on color and clarity. Weakly made and chipped diamonds are also segregated at this stage. Quality is paramount, and hence, meticulous attention is paid to sort only well-made assortments by clarity to create usable batches.

Re-manufacturing the Weak Makes

Diamonds that are found to be weakly made or chipped aren't discarded; instead, they undergo re-manufacturing to meet quality standards. This is an extensive process that includes:

- Stone Planning: Each diamond is planned to maximize yield and improve its quality.

- Shaping: Lasers are used to shape the diamond, especially if its original shape needs alterations to meet quality standards.

- Polishing: The diamonds' top and bottom are polished to give them a fresh, new appearance.

- Quality Control: After the diamonds are re-manufactured, they go through a stringent quality control process. Only the diamonds that meet all quality criteria are integrated back into the usable assortments.

Business Benefits of Diamond Recycling for Jewelers

Cost-Efficiency

One of the most immediate benefits is cost reduction. Sourcing recycled diamonds eliminates the costs related to mining and raw material acquisition. This saving can be passed on to businesses and consumers, making your products more competitive.

Ethical Standards & Environmental Stewardship

In an era where consumers are increasingly concerned about ethical sourcing, recycling diamonds allows jewelry companies to maintain high ethical standards. It serves as an alternative to conflict diamonds and reduces environmental degradation caused by diamond mining.

Versatility and Inventory Management

The recycled diamonds can be fashioned into various shapes and sizes, offering a more versatile inventory. The re-manufacturing process ensures that even weak or chipped diamonds are restored to high-quality stones, reducing waste and improving inventory turnover.

Brand Image and Marketability

Adopting a sustainable approach to diamond sourcing significantly enhances the brand image. Companies can market their products as eco-friendly and ethical, which is an increasingly attractive proposition for both B2B and B2C customers.

Wrapping Up

The process of recycling diamonds is not just an environmentally friendly practice; it's a strategic choice for jewelers that offers economic benefits, enhances brand reputation, and meets the growing demand for ethical sourcing. In the world of precious stones, where quality and purity are celebrated, integrating recycled diamonds into your business model makes perfect sense. After all, what could be more pure than giving a diamond a second chance to shine?