Why Outsourcing Certain Diamond & Jewelry Jobs Makes Good Business Sense for Jewelers

Outsourcing always makes good business sense for companies, both big and small. Generally speaking, outsourcing improves efficiency, reduces costs, and allows companies to focus on their core business.

Not only does contracting out specific tasks save time and money, resulting in lower overhead and staff labor costs, it also allows businesses to tap high-caliber talent for project-specific work. Outsourcing allows a business to expand its team temporarily and strengthen areas of expertise as needed.

Outsourcing empowers jewelers to benefit from the latest technology by leveraging the equipment and expertise of trusted production partners who do these tasks regularly, without jewelers having to make those capital investments.

Farming out specific skilled tasks also eliminates the need for time-consuming training in-house, ensures the work is done correctly, and helps businesses achieve their primary objectives more efficiently.

Demand for Diamond Services

“No business keeps maximum staff on year-round, the same with jewelry production,” says Benjamin Burne, CEO and founder of White Pine Wholesale, a leading supplier of recycled diamonds, pre-owned jewelry, and outsource partner for diamond and jewelry production services. “Most businesses will outsource diamond and jewelry production periodically, even if they have jewelers on staff.”

Jewelers can benefit from outsourcing diamond services to suppliers who perform those tasks every day, notably cutting, sorting, testing, and setting.

Burne says diamond-cutting services are especially in demand. “Jewelers would never have enough re-cutting to justify the investment in equipment and staff, so it makes sense to partner with a supplier dedicated to these services.”

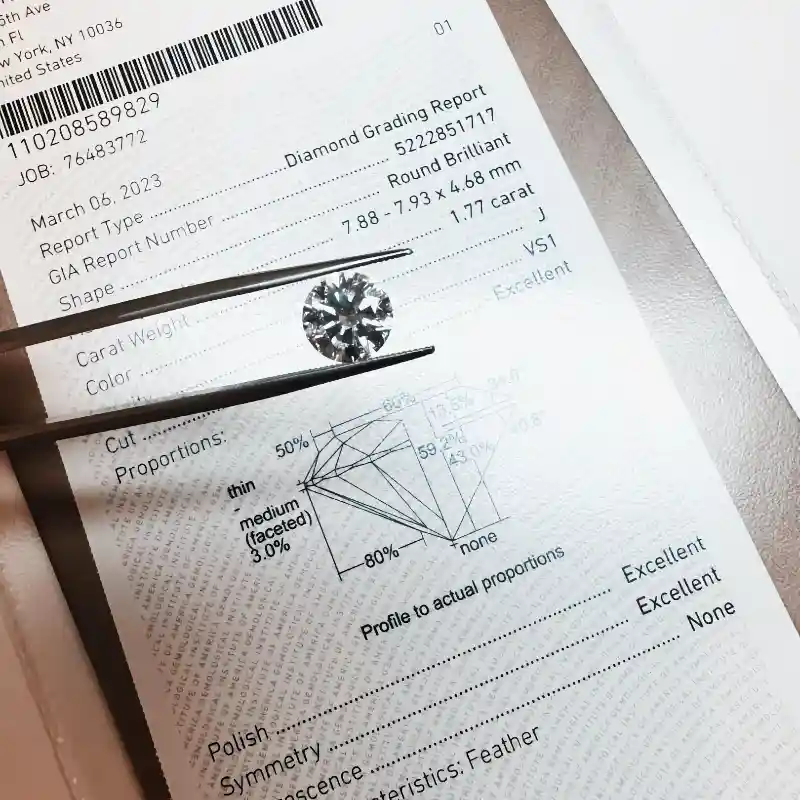

White Pine, for example annually re-cuts thousands of carats of recycled diamonds (broken or of weaker make), with the expertise and latest technology to achieve the precision diamond cut grades demanded by jewelers today, including triple excellent. “If a stone is at a critical weight, we provide options so the jeweler can determine the best economic outcome,” Burne shares.

Jewelers save time and money working with supplier partners who provide diamond-sorting and picking services, customizing assortments by cut, color, and clarity, round and fancy shapes, at the jewelers’ direction to ensure they maximize the value of their parcels, avoiding excess inventory and waste.

Diamond testing for synthetics and jewelry appraisals for insurance replacement values and claims are popular services to outsource, as are suppliers who perform them day in and day out.

CAD & Custom Work Advantage

Jewelers can benefit from working with supplier partners who offer their production capabilities for custom designs like engagement rings, and diamond gold and platinum jewelry for special orders or private label collections.

Suppliers who can guide jewelers through the process — from developing the CAD file to casting, setting and finishing the piece — provide an enormous service and opportunity that can help start-ups to established brands take their ideas from concept to creation. Working with a manufacturing partner can be a major boost for business, satisfying customers’ needs and desires, while allowing jewelers to focus their energy on sales, marketing and relationship building.

Outsourcing diamond production tasks and services to skilled professionals in the jewelry manufacturing industry can be a smart way for jewelers to lower costs and streamline operations, benefit from the latest technology and expertise, focus on core goals, and promote sales growth.